composite

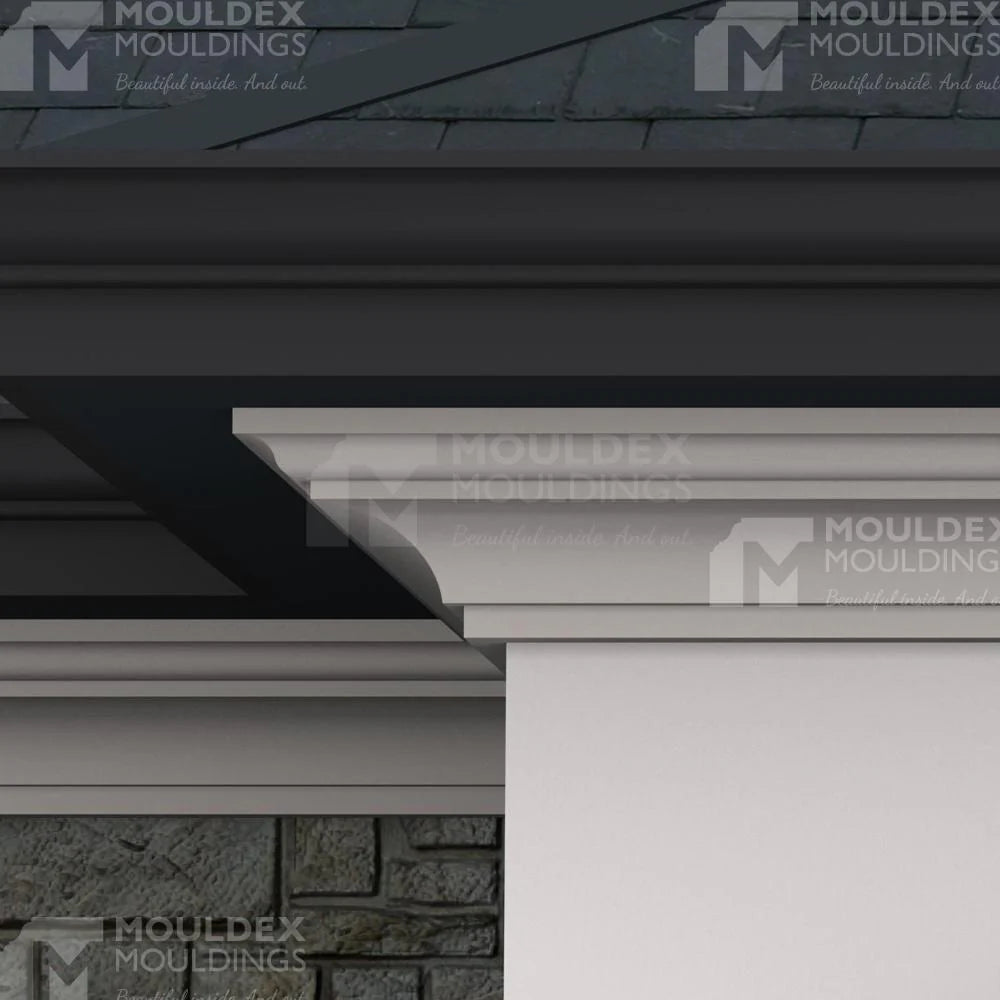

EXTERIOR MOULDINGS

MOULDEX MOULDINGS

featured on the discovery channel

Introducing

MX. CURATED.

Meticulously chosen exterior molding combinations by our team of sharp stylists.

We have professionally assembled each of our trim, sill, middle/center band and cornice/crown profiles into complete styles, taking the guesswork out of matching the right sequence.

WE'RE MORE THAN MOULDINGS

WE HAVE YOUR WALLS COVERED TOO

STONE VENEER

A superior, high-quality stone veneer that’s designed for both residential and commercial properties.

We make building and renovation easy and affordable with beautiful, Canadian-made products that are lightweight, durable, quick to install, and able to create distinctive, individual features, inside or outside.

THIN CLAY BRICK

Our beautifully reclaimed thin brick veneers for exteriors and interiors re-define tradition while maintaining class.

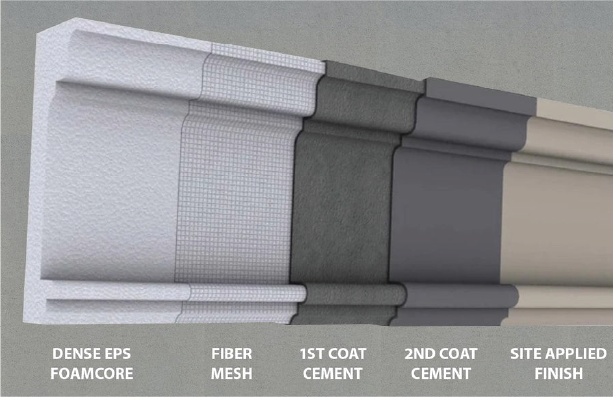

THIS IS HOW WE DO IT.

STAGE 1 - DENSE FOAMCORE

We have cut profiles as small as 1" to mouldings as large as 4' since we opened our doors in 2001. This process is completely computer controlled leaving no room for error.

STAGE 2 - MESH

An adhesive technical mesh is applied by manually pressing it into the shape. This is done for a couple of reasons. The first and most important is that it provides a bond for the cement coating.

STAGE 3 - FIRST COAT

An extrusion process that is controlled by highly skilled operators on our coating line. First coat is generally 3/16" - 1/4" thick, completely engulfing everything except the back of the shape.

STAGE 4 - SECOND COAT

After a 24 hour cure period, we can begin to apply a second coat to our mouldings. The final coat is strictly skimmed on, making for a smooth finish, ready to apply and paint.