WHAT IS THE BEST COMPOSITE MIDDLE BAND MATERIAL?

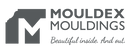

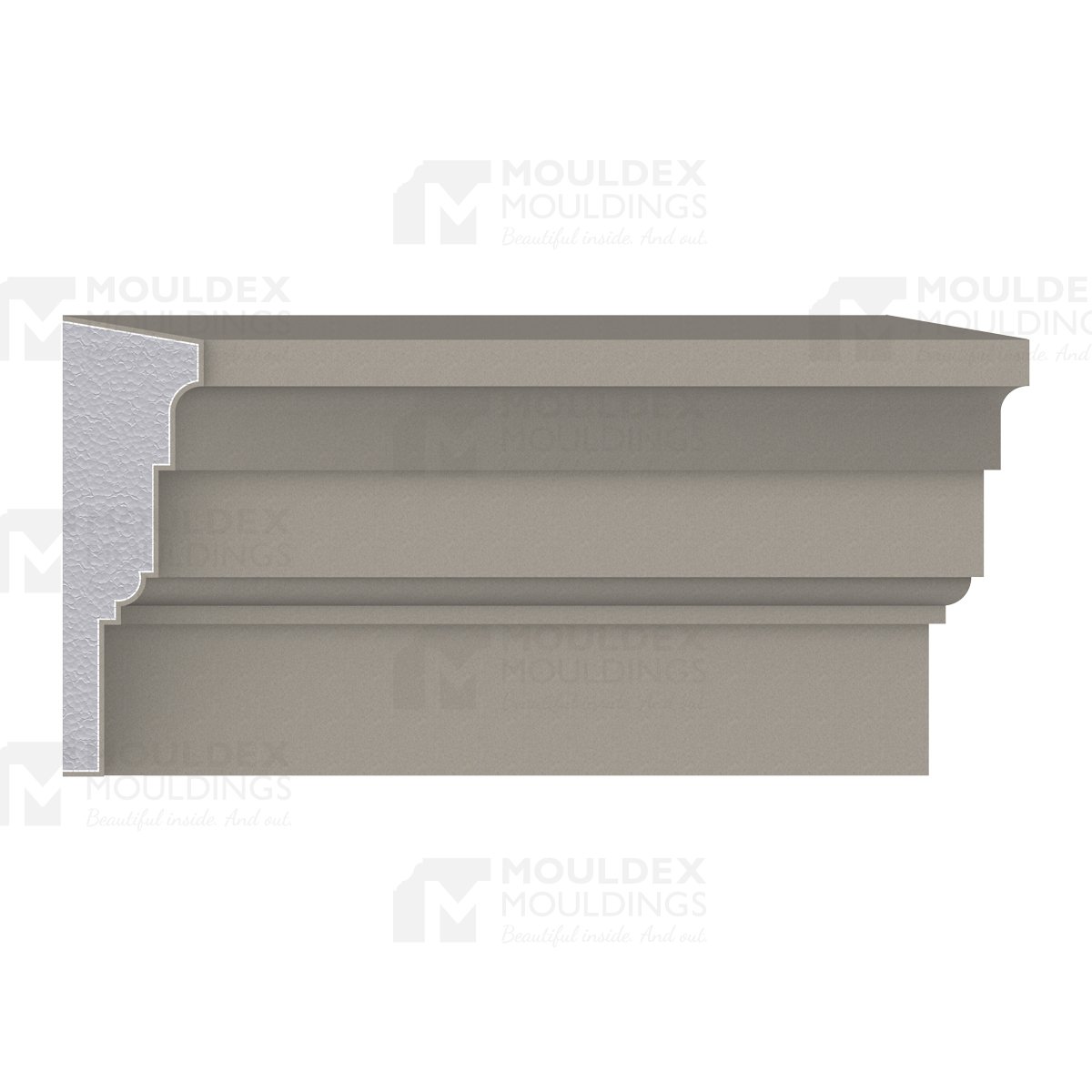

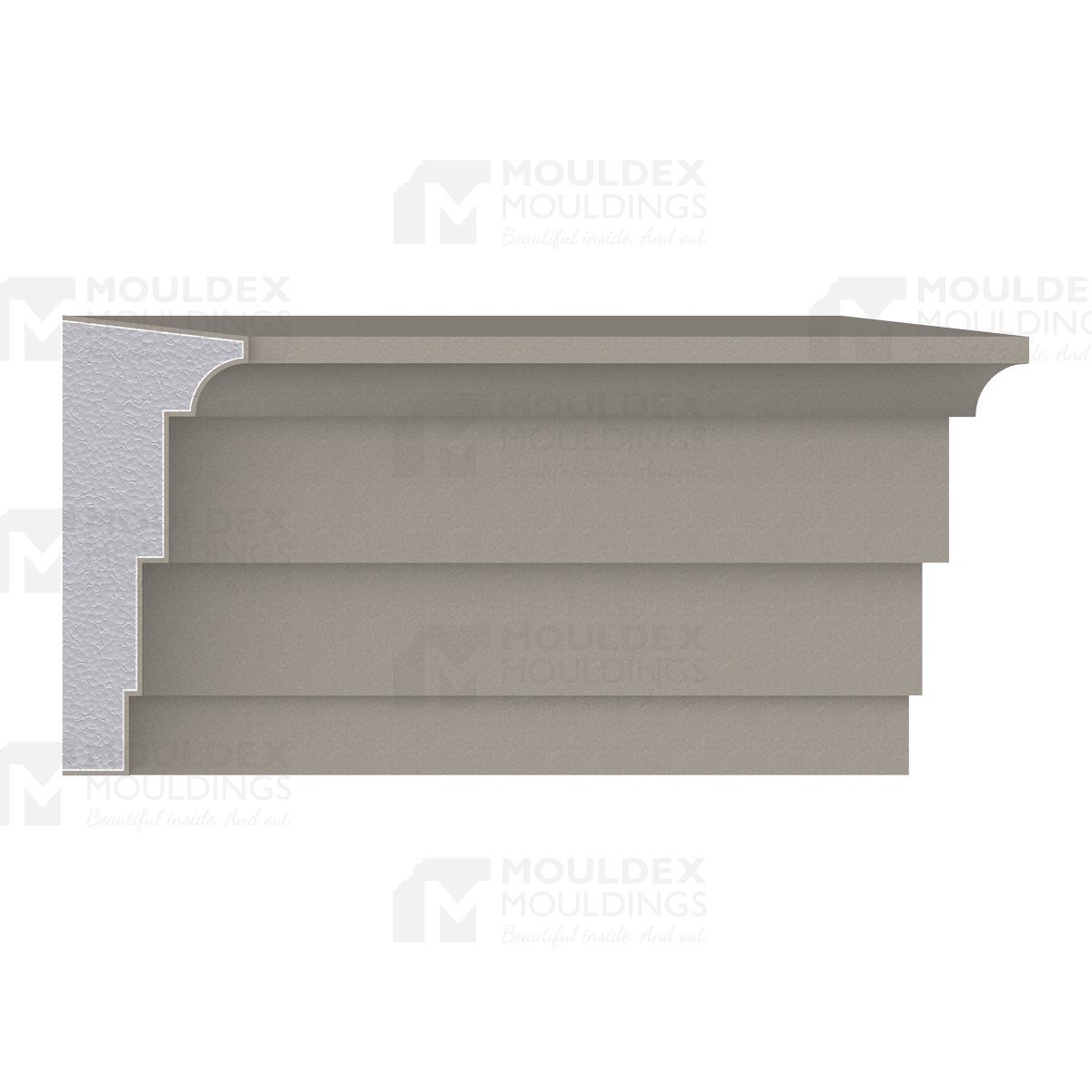

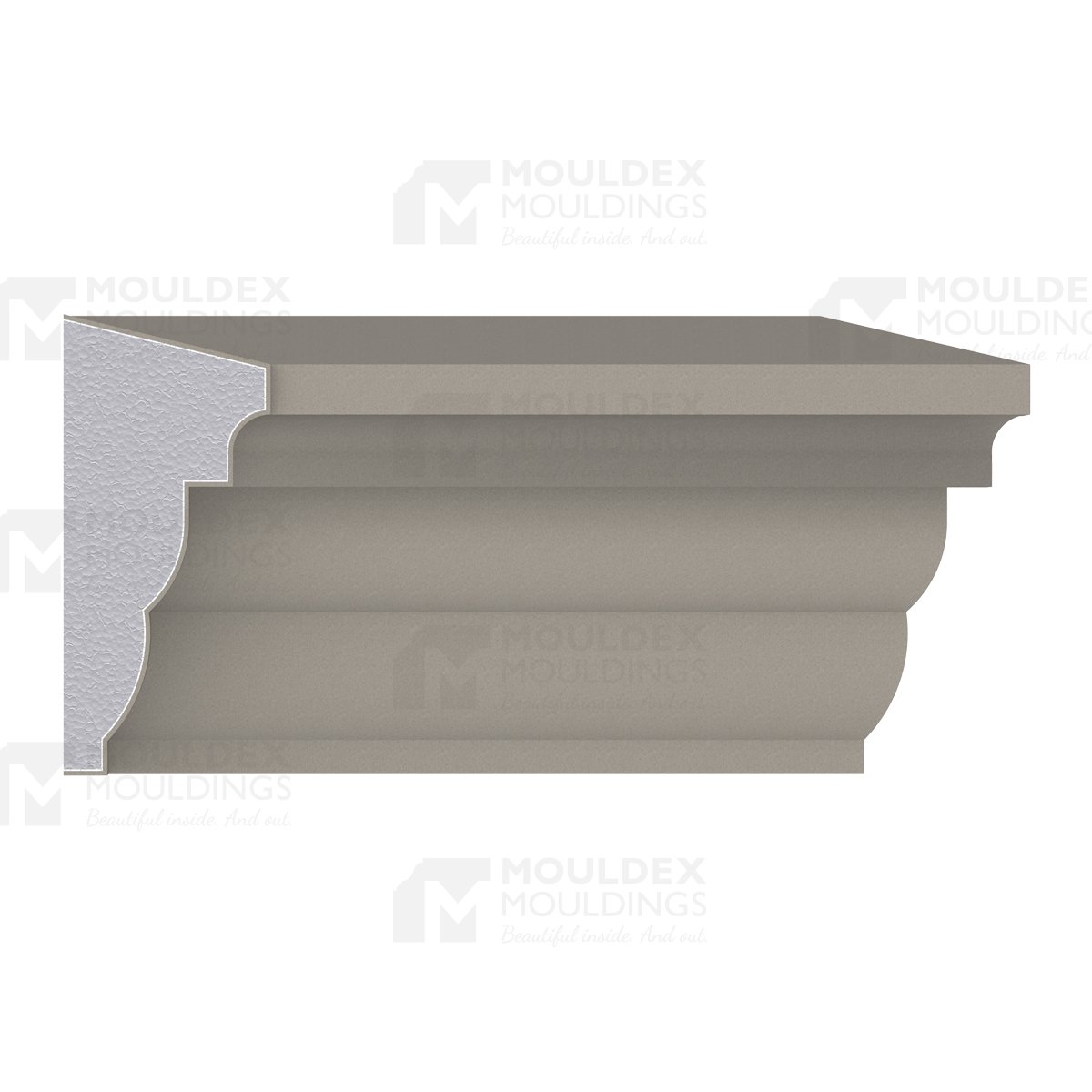

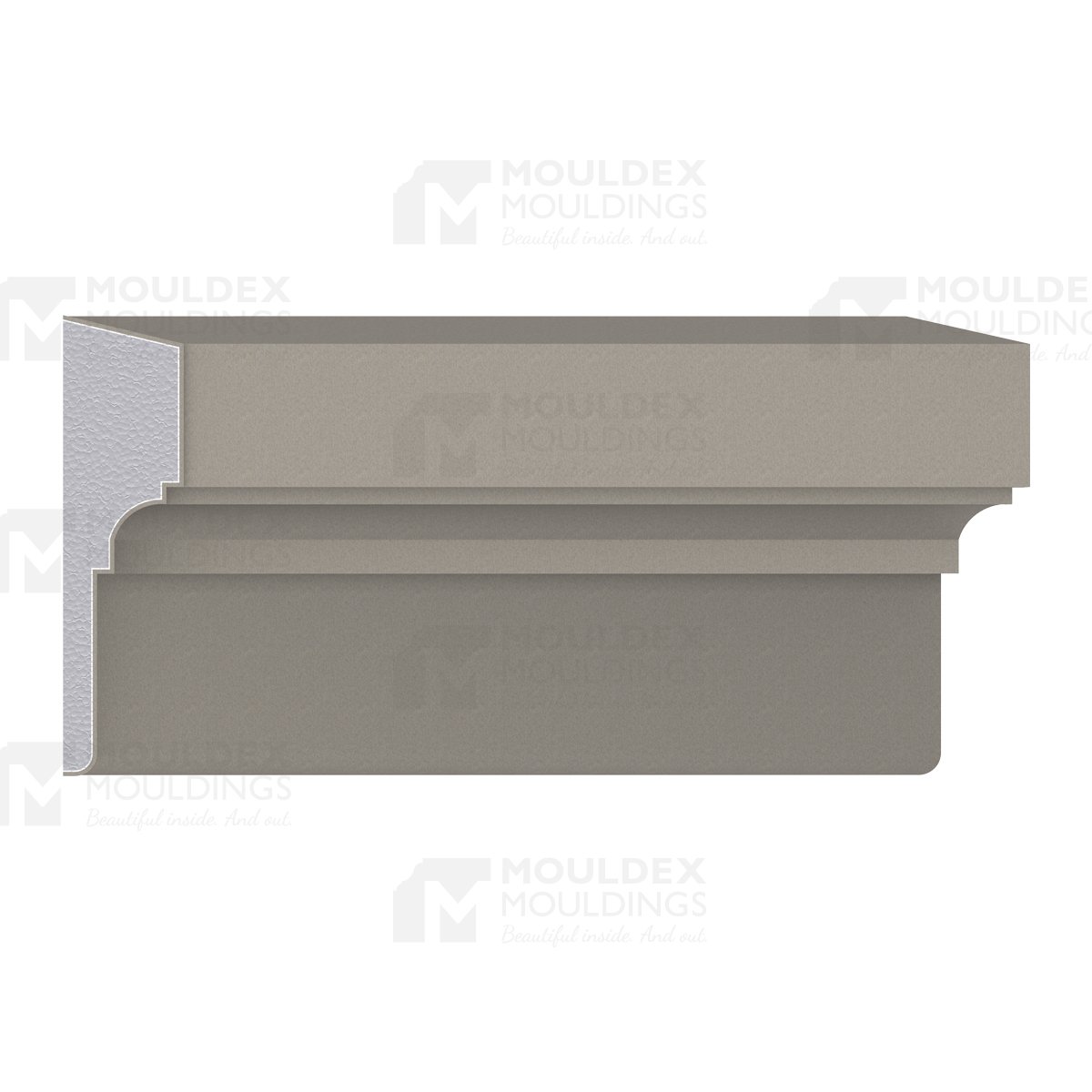

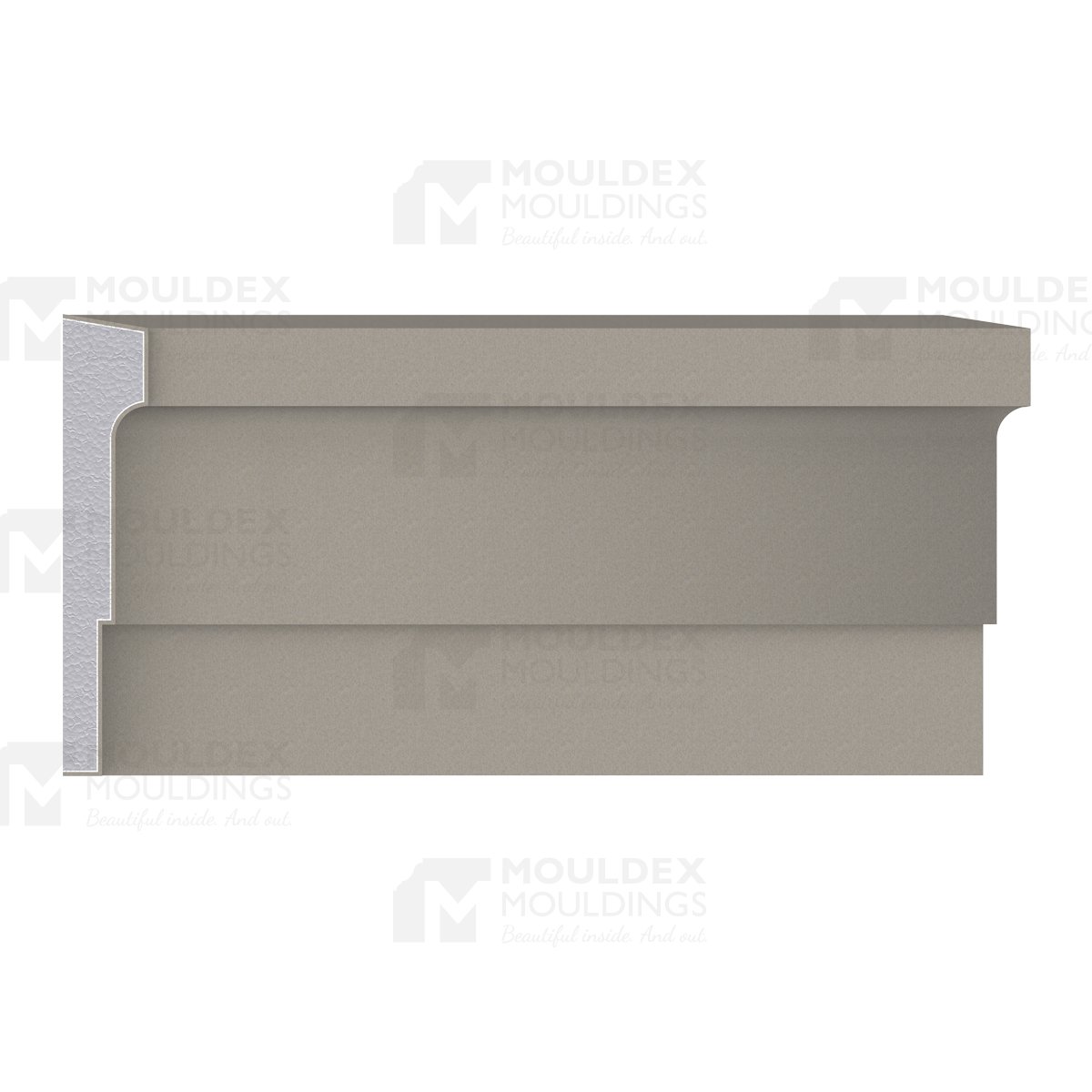

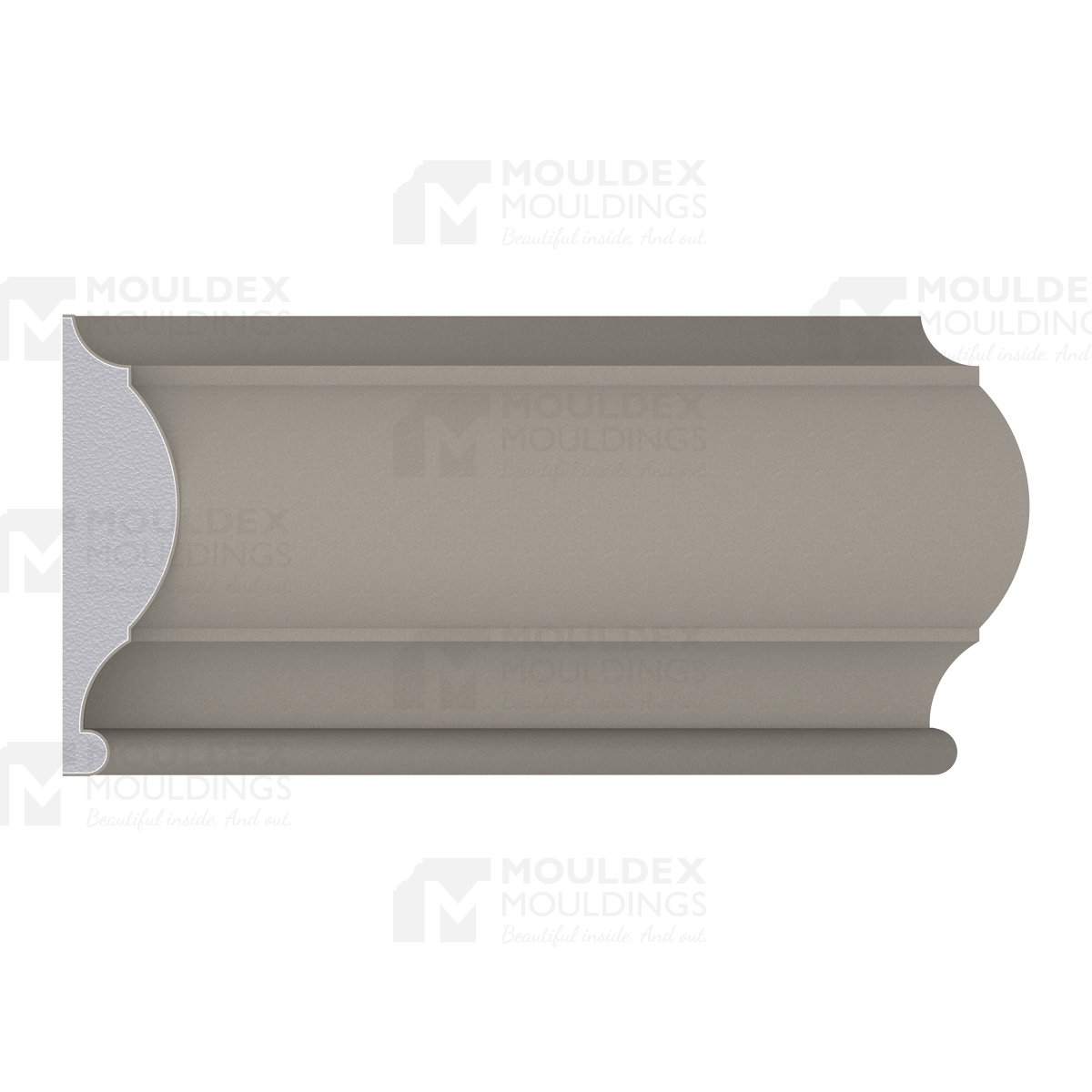

Exterior middle bands, commonly referred to as center bands, are architectural elements typically installed between floors on a building's façade. These features are particularly valuable in enhancing structures with expansive, undecorated surfaces by adding dimension, depth, and detail. They play a crucial role not only in elevating the architectural aesthetics but also in providing a seamless transition between different materials used in construction.

Middle bands serve a dual purpose. Aesthetically, they break up large, monotonous wall spaces, adding interest and elegance to the building’s exterior. Functionally, when a wall features two different building materials, such as brick on the lower floors and stucco above, a middle band creates a clean, deliberate transition. This can help manage materials that have different expansion and contraction rates, reducing the potential for cracking and weather damage.

Superior to Wood

Unlike wood, which is susceptible to weather-related damage including warping, rotting, and splitting due to moisture and temperature fluctuations, Mouldex Mouldings are entirely synthetic and impervious to these conditions. Our composite mouldings require no maintenance, unlike wooden counterparts that need regular painting and sealing. Additionally, Mouldex can manufacture larger profiles in a single, seamless piece—an option not feasible with wood, where multiple pieces must be joined, increasing the risk of splitting and decay over time.

Advantage Over Precast/Stonecast

Compared to heavier precast or stonecast alternatives, Mouldex mouldings are remarkably lightweight, eliminating the need for costly support mechanisms or heavy-duty machinery for transport and installation. This not only reduces the overall cost but also simplifies the installation process, making it quicker and less labor-intensive. In terms of cost-effectiveness, our mouldings are approximately 25% of the total cost of stonecast products when considering all aspects from design through to installation.

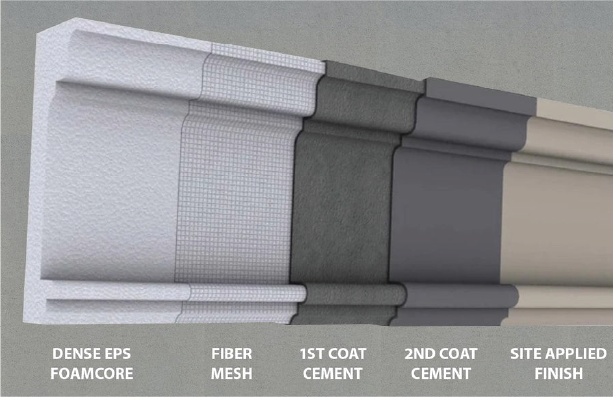

Comparison to PVC/GFRC/Fiberglass

While PVC, GFRC (glass fiber reinforced concrete), and fiberglass options might initially seem viable, they also require the assembly of multiple profiles to achieve larger mouldings. These materials are prone to damage under environmental stresses such as precipitation and temperature changes, leading to splitting and necessitating eventual replacement. Mouldex mouldings, however, are designed to withstand these elements without the associated wear, maintaining their integrity and appearance over time without the issues of expansion and contraction that affect other materials.

CUSTOMIZATION

Mouldex isn’t just about offering superior products; we’re also leaders in customization. While our catalog features a variety of pre-designed window trim mouldings, our expertise shines in tailoring these to meet the specific needs of our clients. Whether you require slight modifications to existing designs, wish to replicate an historical profile, or need a completely unique moulding crafted, our team of experts is equipped to deliver precise, high-quality custom solutions.

With an average order fulfillment time of just 7-10 days, Mouldex is committed to not only meeting but exceeding the expectations of architects, builders, and property owners alike, ensuring that each project achieves both functional requirements and aesthetic aspirations.